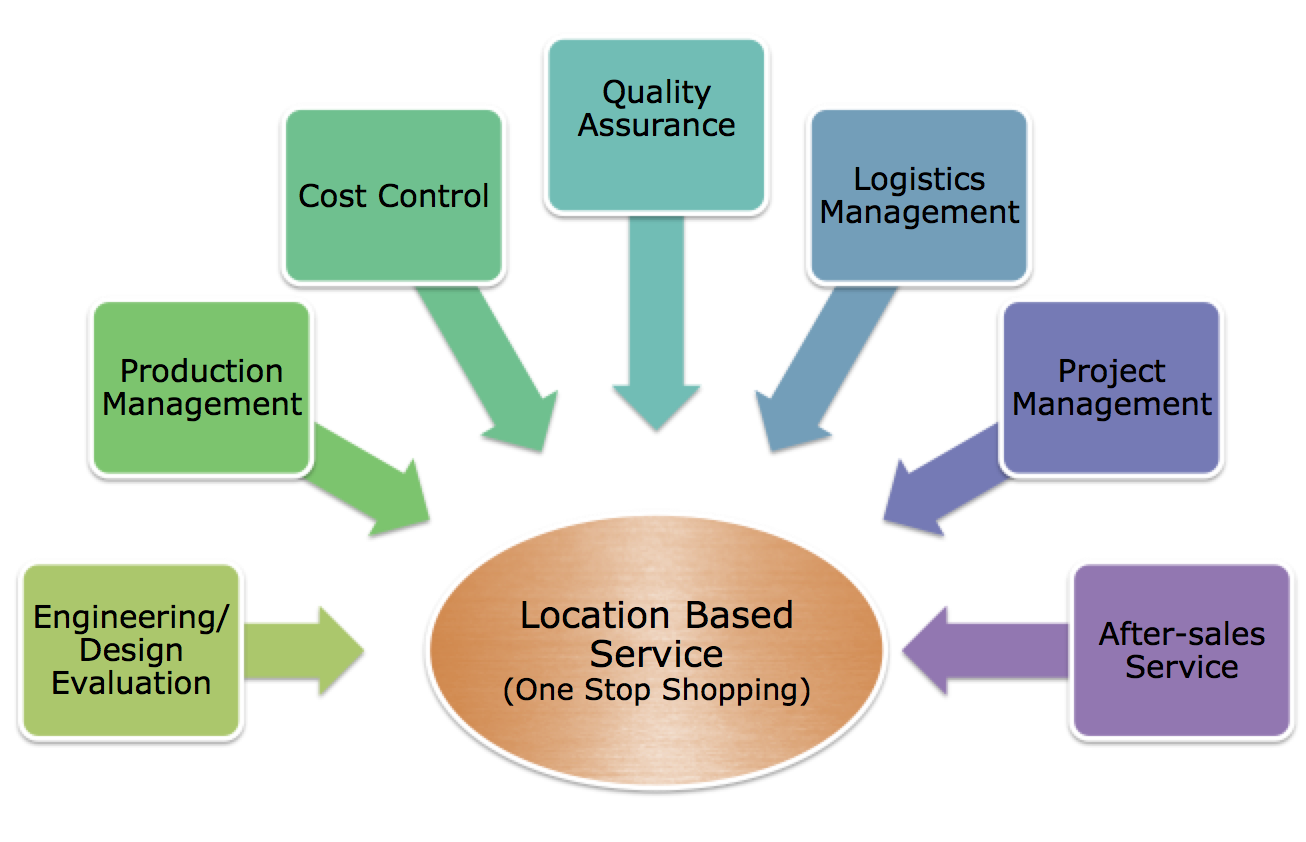

- Engineering & Design Evaluation:

We treat any inquiry as the baby of parents. So, once we receive new product inquiry from customer, ICS team will firstly require engineering prints, 3D files or samples for engineering evaluation at this stage. In order to ensure all the details of design are considered, as well as providing our engineering solutions to some critical dimensions or design if necessary. Our added value is bringing your concept to production perfectly.

Production Management:

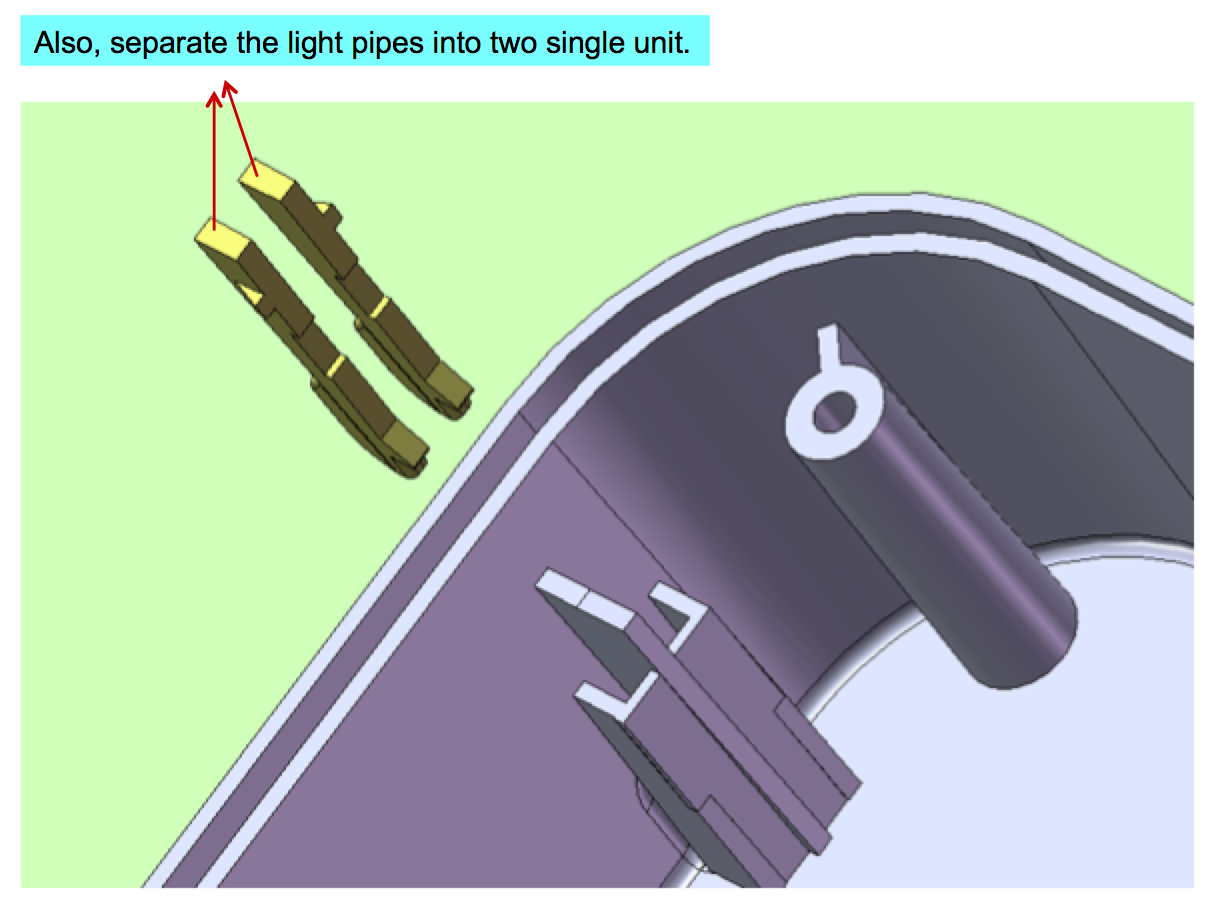

According to our experience, good production management normally reducing cost and quality risk. You don't need to transfer your separate products hundreds miles away for assembling. With multiple production capabilities in Precision Machining, Casting, Forging, stamping and other produciton process, we can offer more flexible and efficient production options for your special order requirements.

According to our experience, good production management normally reducing cost and quality risk. You don't need to transfer your separate products hundreds miles away for assembling. With multiple production capabilities in Precision Machining, Casting, Forging, stamping and other produciton process, we can offer more flexible and efficient production options for your special order requirements.

Also, with raw material inventory control and logistics management, ICS accept fast delivery for your rush orders or low MOQ production for different selling markets and decreasing your stock pressure.

- Cost Control:

Competitive cost is always the advantage that ICS offers to customers.

The production cost is obviously lower than North America and Europe, also by raw material inventory control and long-term cooperation with outsourcing supplier chain, ICS offers customers competitive cost than big size facility or your local suppliers but still keep equal or better quality.

Quality Assurance:

It is really all about quality!

ICS always takes “No quality, no business” as our business policy. We offer ISO9001 and TS16949 certificated contract production lines for injection molding, and precision machining to provide high quality and high tolerance products. Additionally, all our suppliers are regularly visited on-site and rigorously screened to guarantee that they provide only first class manufacturing services and strategic sourcing to meet our performance requirement.

For every new project from customers, we will provide first article sample with dimension report to customer for mass production approval, as well as inspection report for production shipments.

Logistics Management:

We coordinate shipments efficiently to save customers’ transportation lead time and cost, and allows proper or customized product packaging to protect goods from damage during transportation. For your special requirement, we can deliver your products to single or multiple locations throughout the world.

We work with several contracted carriers and forwarders to find the best, most cost-effective shipping service for your projects. Our logistics experts work to eliminate delays, which gets your shipment where you need them as efficiently as possible.

Project Management:

We believe our offshore manufacturers are qualified to be your OEM and ODM supplier and accompany with our skilled and experienced

project management service abd strategic sourcing for either your single component or turnkey product development. Our team can precisely control every process from initial inquiry, engineering evaluation, quotation, purchasing , sample (tooling) stage, pilot run, mass production, inspection and shipment. We will help you transform your concept into a tangitile product.

After-sales Service:

Our business policy is long-term relationship but one-order business. We take after-sales service as a responsibility to customer, such as quality complaint, mold/tooling maintenance, product modification, design change, supplier sourcing and more.

To satisfy our customers and make you working more efficiently is our main policy. Therefore, leave the difficulties to us, save more time for yourself!!